Home > Blog

Read Time — 2 minutes

Is Your Shop Floor Operating At Peak Performance?

A strong ERP can help you with everything from quotes to cash, but what if there was a way to view the utilization of each individual machine on your shop floor? Well then, you could improve data visibility and make forward-thinking improvements while also ensuring that your data is accurate.

Beyond new machines: Exploring the untapped potential in your shop

Think about your current shop machines; do you have the information you need on your machines? Do you have the data to support adding that additional machine? Imagine the insights you could gain if you had visibility into each machine’s performance directly from your office.

The common reflex to low production is to consider purchasing a new machine. However, this approach can overlook the root causes of downtime, which aren’t always related to the number of available machines. Sometimes, the utilization you seek is already there; it just needs to be optimized with accurate data.

At All Metals Fabricating, a Texas-based metal fabrication manufacturing company, Lance Thrailkill saw an opportunity for continuous improvement in his shop. All he needed was the data to understand where his shop was over and underperforming. Within the first six months of integrating machine intelligence, Lance improved utilization rates across the shop floor by as much as 152%.

“People like to know how they are doing and see improvement in their performance; this gives them something that they can see in real-time, all the time, and it makes everyone want to do better,” explained Lance. “Awareness fuels the conversation, and the metrics raise questions about what else we can do to improve. For example, our operators realized we needed additional standardizing on tooling. With that and some reorganization, we gained efficiency, driven by the operators and not management.”

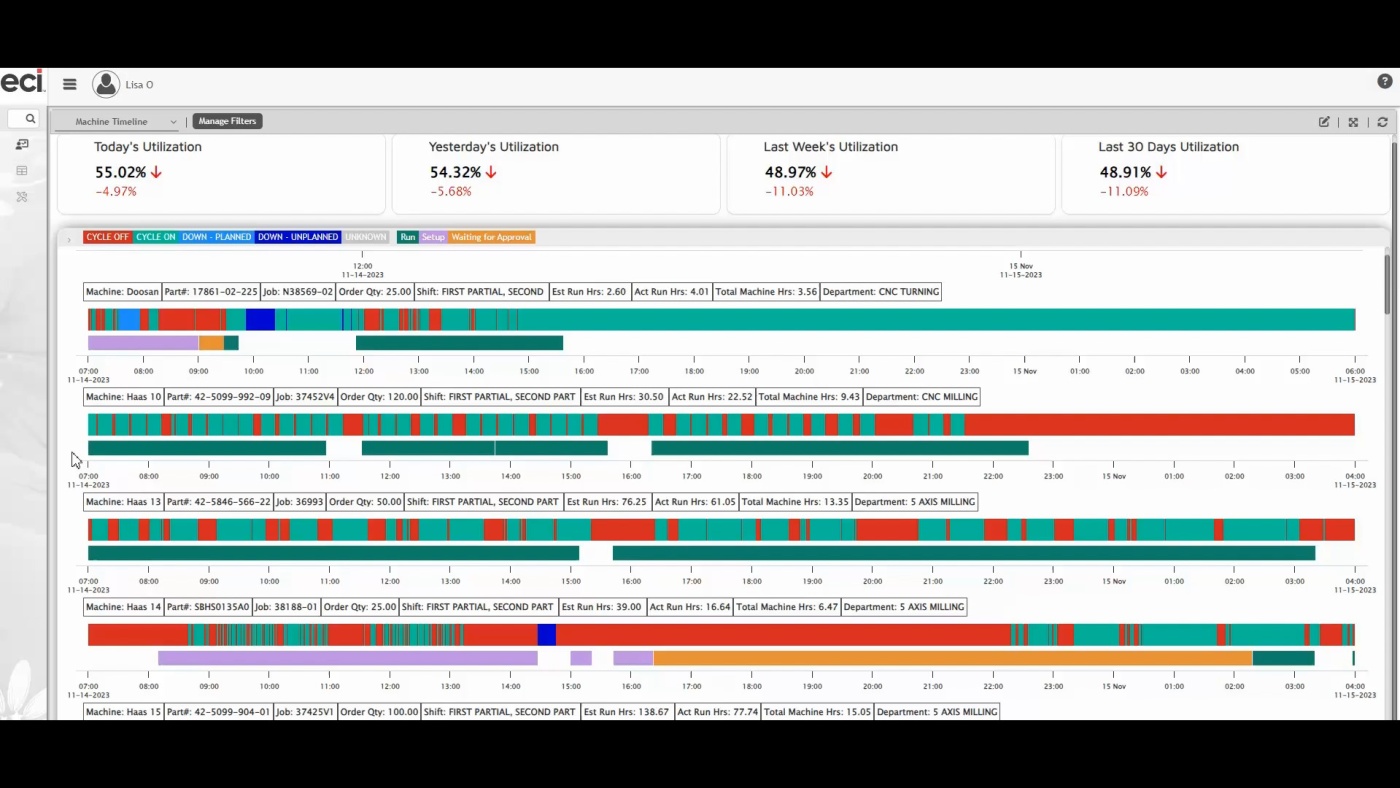

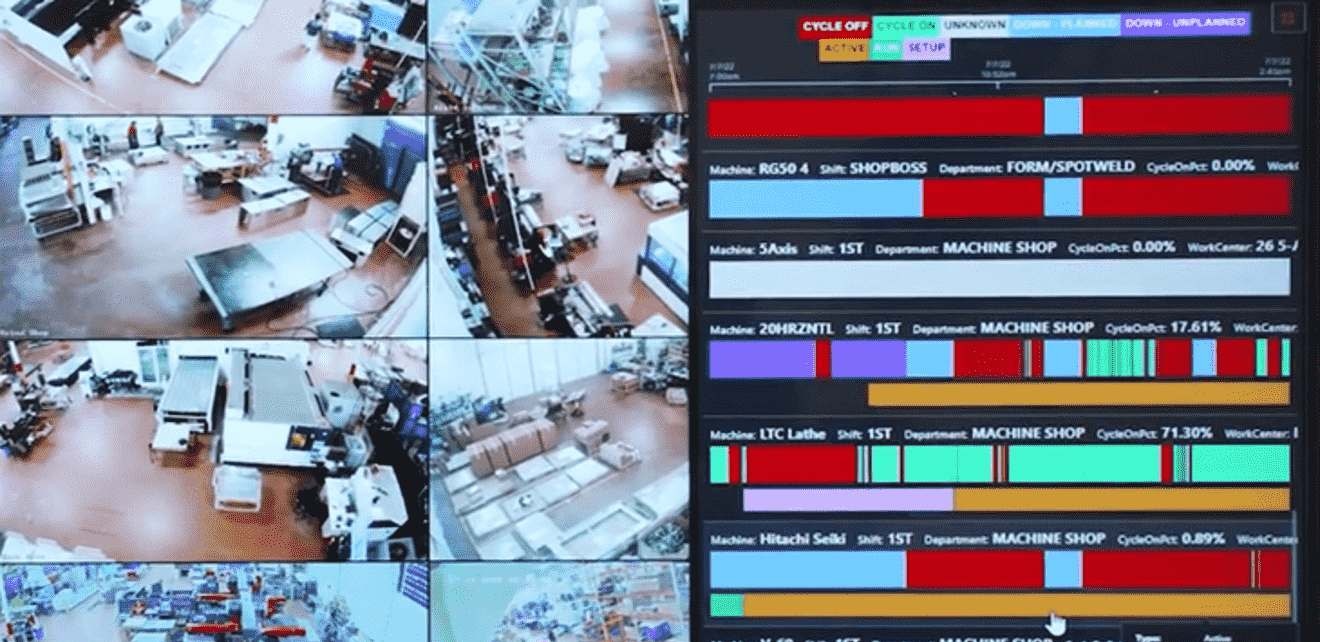

Alora, machine intelligence for manufacturers, connects to your machines so you can see real-time machine performance. On one screen, you can see when employees are logged in and compare it to the machine usage at that time, calculating accurate productivity.

Now, you can see if an employee forgot to log out of a job based on machine usage. These mistakes are more easily caught and corrected, leading to quicker fixes with job costing and more accurate reporting.

The Alora impact

Many of our Alora customers regularly analyze patterns with employees and machines to optimize continuously. Because of the data visibility, customers can improve utilization rates across the shop floor. Alora can also identify the reasons for downtime, so you know what needs to be fixed.

Alora also helps you do more with less as you fully utilize your machines before buying a new one. Then you don’t have to hire more staff. Couple machine data with employee data to optimize your shop, save money, and efficiently allocate resources, with Alora.