Home > Blog

Read Time — 6 minutes

SDS and GHS Labeling with Deacom ERP

For manufacturers and distributors of hazardous materials, Deacom ERP software provides support for the creation and management of Globally Harmonized System (GHS) Labels and Safety Data Sheets (SDSs). Revised in 2012, the Federal regulations provided by the Occupational Safety and Health Administration (OSHA) include a set of guidelines for the communication of information on these hazards. In this blog post we’re going to provide a technical overview of how we help our customers manage this requirement in the software.

To begin, it’s helpful to have an understanding of the 16 required sections that are to be included in every SDS. They provide information such as chemical properties, physical, health and environmental hazards, protective measures, and safety precautions for the transportation, handling, and storage of the product. Those sections are:

- Identification

- Hazard(s) Identification

- Composition/Information on Ingredients

- First-Aid Measures

- Fire-Fighting Measures

- Accidental Release Measures

- Handling and Storage

- Exposure Controls/Personal Protection

- Physical and Chemical Properties

- Stability and Reactivity

- Toxicological Information

- Ecological Information*

- Disposal Considerations*

- Transport Information*

- Regulatory Information*

- Other Information

*(non-mandatory)

A full description of each of these sections can be reviewed on OSHA’s website.

Our Approach Towards Implementation

Comparing SDS – The first step to implementing GHS/SDS is to compare the Deacom generic Safety Data Sheet that we provide to your current SDS. Regardless of the OSHA requirements and guidelines, not all customers will display their information in the same manner. This initial process will help us understand any special requirements regarding where the data should be entered, whether it be on the regulatory item, raw material, or finished good.

Configuration – In Deacom, all GHS and SDS information is stored and printed in the software by utilizing Item Master User Fields, System Constants, and User Calculations.

User Fields – In addition to the default fields provided in Deacom, user defined fields allow you to enter and store information and are available on various master data records. These fields are used to store data for the 16 sections of the Safety Data Sheet including regulatory items, raw materials, and finished goods.

System Constants – In Deacom, system constants are used to define scenarios or calculations where a consistent or constant value is known. All OSHA assigned precautionary statements are added in as system constants so that they will print on the SDS part form and their associated codes can be used to determine which code is associated with each hazard classification. System constants are generally not changed because the Precautionary statements from OSHA are not updated on a regular basis, however some information such as Emergency contact information from Section 1 would be configured here and would only need to be set up once.

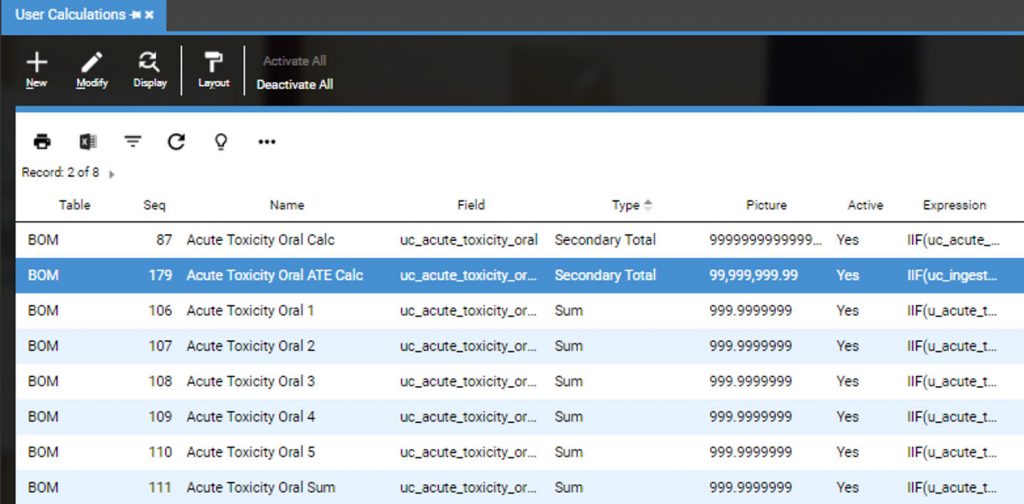

User Calculations – we find that most customers will only have calculations for Section 2 of the SDS, but they can be set up for bringing information from regulatory items, raw materials, and sub-assemblies to the finished good. They are used to determine the hazardous classification for the finished good based on what was selected on the raw material or regulatory item.

User calculations for Section 2 are pre-configured based on what is defined in OSHA’s “Purple Book.”

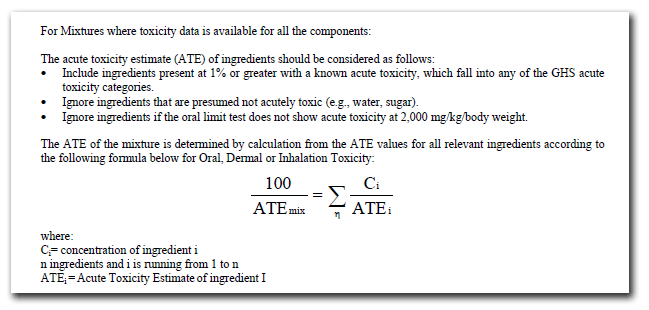

An example calculation for the acute toxicity estimate provided by OSHA.

There are two sets of BOM user calculations for determining the classification based on the regulatory or raw material components. The first set determines the weight percentage of a classification across all regulatory/raw materials. The second set determines which classification should be displayed on the GHS Label or SDS based on OSHA rules. For example, you would only classify Acute Toxicity Category 1 if there is more than 1% of that category in the mixture.

There is one user calculation for every category to calculate the weight percentage of a classification. For example, there are 5 categories for Acute Toxicity Oral and therefore there are 5 user calculations to determine how much weight of each possible classification there can be. For every classification, there is a sum calculation to capture fractions and report the lowest classification for precautionary measures. These are not required and can be deactivated as needed.

Importing Data – One of the most important pieces of the GHS/SDS implementation is importing the data accurately. For those customers currently in implementation, the Data Conversion Specialist on your project team will work with you to map the data from your current environment into the Deacom database. If there is no data in a database to map, an import document is provided where all data can be defined and imported using existing processes.

Form Design and Printing

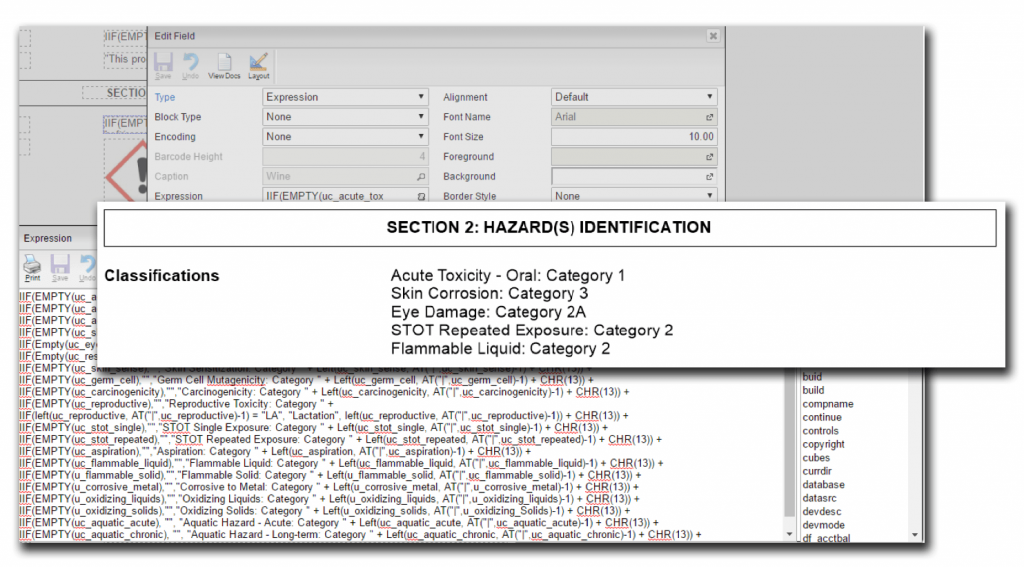

Deacom’s built-in Report Designer is used to create the forms that are in turn used to create the GHS Labels and Safety Data Sheets. Since GHS and SDS are very similar in regards to displaying Section 2 information and some firefighting measures, we always begin with implementing the SDS first and subsequently bring that information over to the GHS Labels.

SDS Form Design – There are three main form designs to the SDS: Section 2, printing regulatory/raw materials and data entered on that level (examples would be Section 3 and LC/LC50), and printing data entered on the finished good. In all these areas, Deacom relies on its system of expressions to pull in the appropriate classifications, pictograms, hazard statements, precautionary statements, CAS numbers, etc.

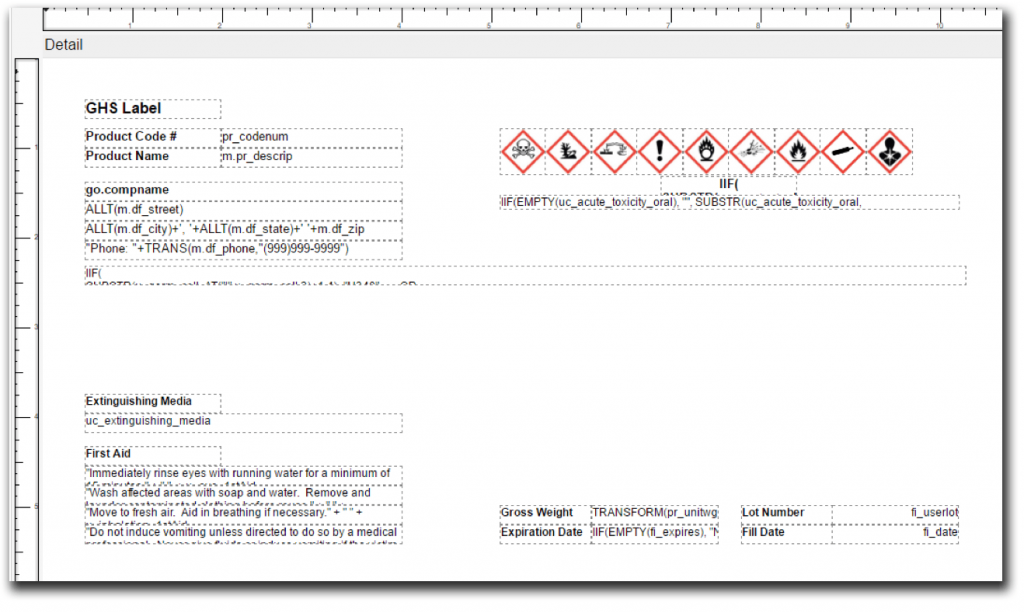

GHS Form Design – GHS Labels contain most of the information from Section 2 of the SDS and sometimes will display information from additional sections, such as first aid or extinguishing measures. The expressions from the SDS are copied over to the GHS during implementation and formatted slightly based on how you would want it displayed.

Printing GHS Labels and Safety Data Sheets

GHS Labels and SDS forms can be printed from multiple locations within the ERP software.

GHS Labels can be printed before or during finishing a job through the Job Labels feature. The labels can also be printed as sales order labels at either the order detail level or during shipment.

SDS forms can be printed via the Print Outs menu > SDS Forms. From here you would simply select the part and formula and then click print. You can also print SDS through document groups before or during shipping. Finally, you can assign customer specific SDS’s through customer part cross-references that can be printed before or during shipping.

The Advantage of a Centralized ERP Platform

Chemical manufacturers have a responsibility to identify any hazards for the products they produce and communicate that information to their customers, employees, and other parties. As a centralized ERP platform, Deacom ERP is constantly being improved to reduce the risk of process control failure by keeping the largest set of functional capabilities native to the system. The reporting and document management tools that live in Deacom provide you the ability to automate the creation of SDS and GHS labels. This will ensure the likelihood of errors due to manual processes is greatly reduced, if not completely removed.

Contact us today to learn more about Deacom ERP software.