How can we make it easier for you to do business?

Manufacturing Operations Software to Improve Performance

With manufacturing operations management software features built into Deacom, you can maintain full visibility of batch production, labor tracking, MRO, and more, all from a centralized location.

Alerts and Automation

The integration of KnowledgeSync for alerts and triggers can help streamline your business and enable real-time updates across your entire organization.

- Remain up to date with your purchasing cycle

- Track and address activities throughout your production process

- Instantly know what is going on with your sales and pull specific reports

- Monitor inventory activity

Batch Production

Enable total process control while maintaining production efficiency. Deacom's batch production capabilities enable you to benefit from:

- Exceeding quality standards through process control and quality checks

- Increased manufacturing efficiency while ensuring compliance with regulatory traceability and quality standards

- Enhanced business visibility through real-time production cost and efficiency data for informed decision-making

- Ensuring customer demands are met by having proper inventory levels necessary to meet production requirements

Catch Weight Management

For process manufacturers producing catch weight items, the Deacom AutoFinisher tool provides catch weight software that automatically confirms that the item adheres to the weight specifications maintained within the ERP system. Features include the ability to:

- Receive catch weight values directly from a scale or a machine without vendor configurations

- Manage minimum and maximum weight thresholds directly within Deacom ERP to ensure the data accuracy of finished goods

- Re-queue failed finishes that encountered an error and could not be completed or canceled together

- Monitor the performance of work centers and operators directly within the core ERP software

- Perform tests of the scale reader without a scale, and without interrupting production, using the built-in loopback functionality

- Process job finishes and generates labels offline when a network connection is unavailable

Read a blog about "The Future of Catch Weight" to see how you can optimize your manufacturing processes.

Labor Tracking

With labor tracking in Deacom, you can capture production costs based on machine and labor utilization which gives your manufacturing operations a better understanding of actual versus standard costs.

- Record employee labor tracking by using Deacom’s WMS, mobile, or browser application

- Run production costing reports to compare set standards with actual labor performed

- Update and adjust routings and costs based using a data-driven approach

Manufacturing Execution System (MES) Integration

With Deacom's API integration you can connect production equipment to the ERP system for advanced data analytics. This allows you to:

- Sync Production Inputs - Receive information on lots issued to production jobs for tracking and costings purposes.

- Sync Production Finishes - Receive information on lots finished from production jobs for use with Deacom’s WMS platform.

- Sync Quality and Job Information - Receive data points from the machinery to track the health of the equipment and analyze future system changes that need to be made.

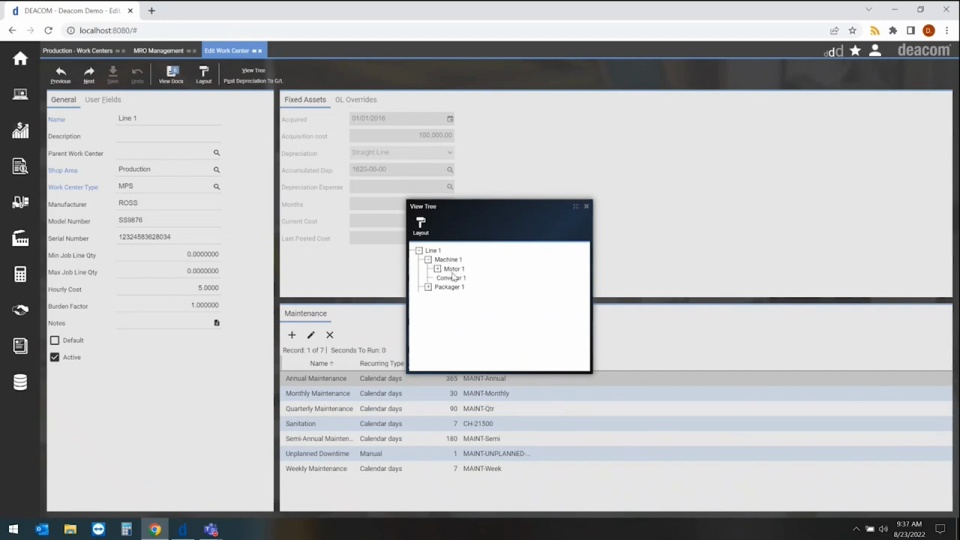

Maintenance, Repair, and Operations (MRO)

Deacom’s MRO software offers manufacturers the tools needed to schedule maintenance and assign the appropriate costs required to efficiently maintain equipment and facilities. Scheduled maintenance times are integrated with the Deacom master production calendar and provide the ability to plan and schedule both production and maintenance work in one, centralized location. In this brief video, we show how this allows for sharing of many of the same systems, such as sharing schedules, using the same purchasing functions, and using the same MRP functions. This also allows for a seamless flow directly into accounting.

Production Weigh Up

The staging and weighing of materials that will be used in the production process is known as production weigh-up. Deacom offers functionality that enables batch and process manufacturers to improve the effectiveness and precision of this process, which is crucial for businesses that are subject to strict FDA regulations.

Product Serialization

Multi-Level Serialization includes all of the functionality needed to utilize serialization within the ERP system. Benefits of having a native serialization capability include the ability to:

- Identify and track serialized goods throughout the supply chain as a more specific record than just a lot number

- Generate and manage unlimited layers of serialization to meet FDA and customer requirements

- Automate the assignment of serialized goods to enable tighter process control

FAQs

How can process manufacturers maximize efficiency with batch tracking and scheduling?

Process manufacturers can maximize efficiency with batch tracking and scheduling by leveraging the capabilities native to the Deacom ERP system. Deacom provides real-time visibility into production processes, enabling manufacturers to track and monitor batch progress, resource utilization, and inventory levels. It also automates the scheduling process based on predefined rules, production capacities, and resource availability and considers factors such as equipment availability, labor resources, and material requirements to create optimized production schedules, reducing manual efforts.

Can serialization software enhance batch tracking and ensure product integrity?

Yes, serialization software plays a crucial role in enhancing batch tracking and ensuring product integrity. By assigning unique serial numbers to individual units, cases, and pallets, serialization integration within the ERP system enables traceability throughout the supply chain. This means that each product can be tracked and traced from manufacturing to distribution, allowing for better visibility and control over the entire batch. This also helps in detecting and addressing any issues or anomalies in the production process, ensuring product integrity, and enabling efficient recalls if needed.

What is catch weight software and how does it benefit manufacturing operations?

Catch weight software is a feature within an ERP system that allows food manufacturers, particularly those dealing with variable weight products such as cheese, to manage and track the weights of their finished goods accurately. It enables manufacturers to record, manage, and report on the variable weights of items. Deacom ERP offers catch weight management by integrating with scales to ensure accurate weight requirements are adhered to during the receiving and finishing processes.

How can catch weight software improve accuracy and control in inventory management for process manufacturing?

Catch weight software can improve accuracy and control in inventory management for process manufacturing by enabling precise tracking and recording of variable-weight items. With catch weight integrated into the Deacom ERP system, manufacturers can capture the weight of each individual unit accurately, ensuring precise inventory management. This allows for accurate calculation of inventory levels, better demand planning, and reducing waste or understocking. The software also enables real-time visibility into catch weight items throughout the supply chain, enhancing control and traceability.

How can an ERP system optimize schedules and labor management in manufacturing?

An ERP system like Deacom can optimize schedules and labor management by providing a centralized platform for planning, scheduling, and resource allocation. You can efficiently manage and allocate resources such as equipment, materials, and labor based on production schedules all from within the software while optimizing production schedules by considering factors such as capacity, resource availability, and order priorities. It helps in reducing downtime, maximizing productivity, and ensuring that labor resources are effectively being utilized. Real-time data and analytics provided by the ERP system enable better decision-making and proactive adjustments to optimize schedules and labor management.

Supercharge your manufacturing operations with our comprehensive ERP system tailored for process manufacturers.

Experience the power of integrated catch weight and serialization software and take your business to new heights.

Testimonials

Graceland Fruit

“Now we can take our inventory control to a specific shop location and we can relieve material used in a production batch a lot more efficiently than ever before.”